In response to rising global demand triggered by Chinese Rare Earth Element export controls, Metalysis has begun commercial production of High Scandium Loading Aluminium Scandium (Al3Sc) Alloy Powder.

The UK company – an end-to-end manufacturer of solid-state metal and alloy powders and global leader in materials science – is based across two sites in South Yorkshire.

It is now producing high-purity aluminium scandium alloy powder (Al3Sc) as Western manufacturers seek secure, non-Chinese sources of REEs and critical minerals.

The UK’s critical mineral strategy: Vision 2035, published last November, commits the UK to building out its midstream as a strategic imperative.

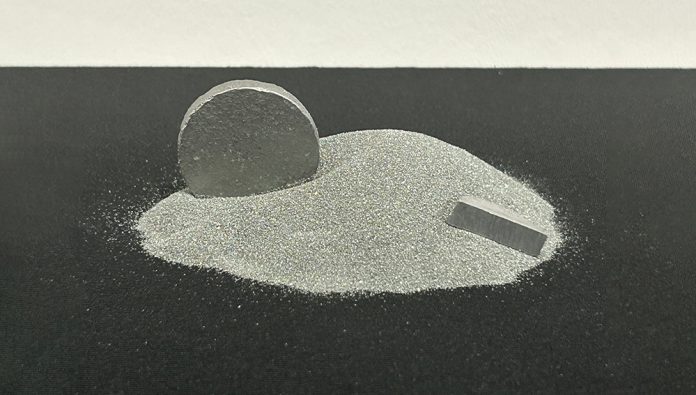

Metalysis currently produces a high scandium-loaded aluminium scandium alloy, currently achieving 36 weight % / 25 atomic % scandium (64 weight % / 75 atomic % aluminium) in fully homogenised form, with oxygen levels at just 500 ppm and carbon at 50 ppm.

This ultra-low impurity content ensures sputtering targets meet the strict quality demands of semiconductor manufacturing. The material is available in powder or consolidated disc formats.

The alloy at 36 weight % / 25 atomic % scandium is in high demand from international manufacturers of sputtering targets which are used in thin film deposition to apply aluminium scandium nitride (AlScN) coatings to semiconductor components.

AlScN delivers next-generation bulk acoustic wave (BAW) filters and resonators with superior piezoelectric properties – essential for advanced 5G and higher network rollout, Wi-Fi expansion, AI applications, and the Internet of Things.

The aluminium scandium alloy can be diluted with aluminium by customers so producing a lower scandium loading and this master alloy edition can be used in aerospace and defence applications.

Unlike traditional melting processes, which require costly scandium metal and face challenges in achieving uniform homogenisation, Metalysis uses its patented FFC Cambridge electrolysis process to directly co-reduce scandium oxide and aluminium oxide feedstocks in a molten calcium chloride electrolyte at 650–950°C.

This solid-state process consumes less energy, allows market-making high scandium loadings, whilst delivering a fully homogenised alloy with consistent performance characteristics.

Metalysis is a midstream asset for the UK and allies – able to process material in the West – circumventing China which controls 90% of the midstream processing market.

Gen 2 units serve as development units and have recently doubled in number at Metalysis to four. At capacity each can produce up to 350kg of Al3Sc annually, with the market for aluminium scandium estimated at 3-4 tonnes a year.

Through its various Gen units, Metalysis is strategically placed to meet this demand. The larger Gen 3 units will enable output of tonnes per year per unit. The company’s largest Gen 4 units can produce tens of tonnes annually so meeting demand as the market grows.

Metalysis recently completed Spark Plasma Sintering (SPS) and hot pressing of its 36 wt % aluminium scandium powder in partnership with RHP-Technology GmbH, to produce discs which demonstrate the material’s physical and chemical properties via this process.

Chemical composition was uniform throughout the disc and relative densities exceeding 98% were achieved. SPS trials were also conducted to achieve 10wt % scandium loadings via dilution with aluminium powder, demonstrating the versatility to produce an array of scandium containing aluminium alloys, in line with market requirements.

Nitesh Shah, CEO, said: “Metalysis has a clear strategy focused on premium critical materials.

“Our aluminium scandium alloy is fully homogenised and extremely low in impurities, making it ideal for high-performance applications in semiconductor manufacturing, whilst defence and aerospace manufacturers are exploring applications of lower scandium loadings.

“The recent REE export controls from China have accelerated urgent adoption of our aluminium scandium alloys, and we are now scaling production to meet this demand, moving from our Gen 2 units today to tonne-scale output from Gen 3 in the coming months.”