The Leipzig-based company pioneers fully electric, modular, non-thermal plasma catalysis reactors that convert CO2 into valuable chemicals while abating hard-to-treat emissions, offering a sustainable alternative to traditional chemical manufacturing processes.

German start-up enaDyne -which specialises in fully electric, non-thermal plasma catalysis technology for sustainable chemical production – has raised €7 million in seed funding.

Founded in 2021 by Philipp Hahn, Christian Koch, Martin Drößiger, and Torsten Lorenz, enaDyne combines expertise in plasma physics, catalysis, engineering, and materials science.

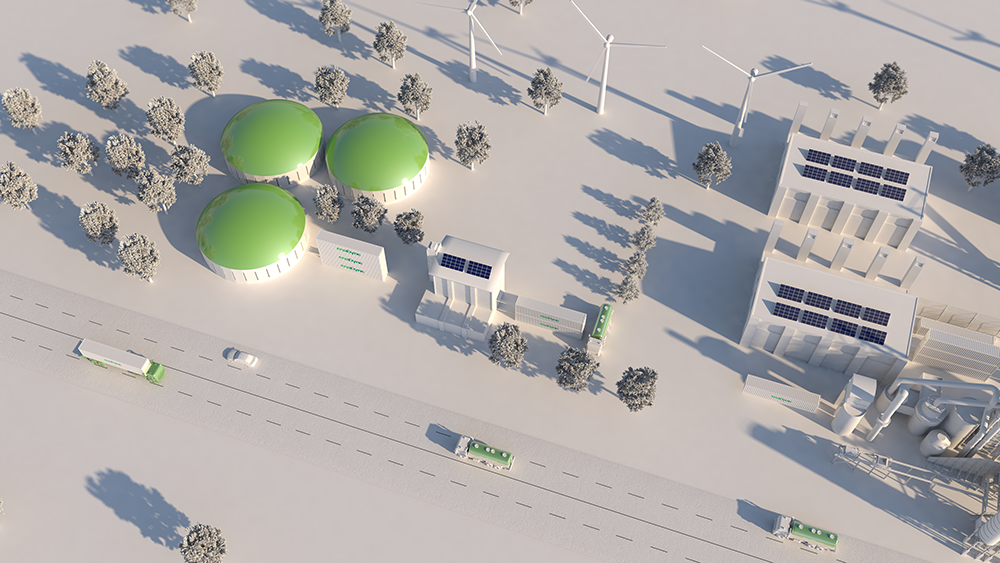

The company has developed a breakthrough reactor technology that converts CO2 and other process gases into valuable chemicals such as syngas, methanol, and ethylene. Its modular, containerised systems also abate hard-to-treat emissions, including CF4 and PFAS, offering a sustainable alternative to traditional chemical manufacturing.

enaDyne’s approach integrates proprietary enaCeramics electrodes with plasma-active catalysts to deliver superior performance. Current results demonstrate CO2 conversion rates exceeding 70% with competitive selectivities, while the modular architecture allows rapid deployment and scaling across industrial applications.

The seed funding round was co-led by Amadeus APEX Technology Fund (a collaboration between Amadeus Capital Partners and APEX Ventures) and Energy Capital Ventures, with participation from Antares Ventures, Possible Ventures, and returning business angels Wolfram Drescher, Andreas Werne, and Sven Sieber.

“What sets enaDyne apart is their precision approach—like using a scalpel instead of a hammer,” commented Wolfgang Neubert, General Partner at APEX Ventures.

“Its non-thermal plasma catalysis represents a fundamental breakthrough in how we approach chemical manufacturing.

“As winners of Germany’s prestigious SPRIND Carbon-to-Value Challenge, they’ve proven this technology can profitably turn industrial waste into valuable chemicals while operating at a fraction of traditional energy requirements.

“This is the kind of paradigm shift the chemical industry desperately needs.”

The fresh capital will be used to build and deploy a 20-foot modular pilot plant at an industrial customer site by mid-2026, develop a first commercial product for plasma-based PFAS abatement, and establish a first scalable production value chain. This comes at a time when the chemical sector faces an unprecedented need to decarbonize.

The global chemical industry generates more than 2 gigatons of greenhouse gases annually(1)—about 5% of global CO2 emissions (2)—while consuming 14% of all oil and 8% of all gas supply as feedstock and fuel (3).

Over 70% of the world’s top 100 chemical producers have committed to carbon neutrality by 2050 (4), yet the sector has underperformed broader stock markets since 2022, with operating margins falling to their lowest levels since the Great Recession (5). These dynamics underline the urgent need for new approaches.

enaDyne’s plasma-based solutions directly address this challenge by enabling customers to produce sustainable chemicals at or below fossil-based costs while significantly reducing emissions from both production processes and persistent pollutants.

“The chemical industry has been locked into fossil-dependent processes for over a century—we’re breaking that dependency with pure electricity and precision,” said Philipp Hahn, Co-Founder and CEO of enaDyne.

“Our plasma technology doesn’t just compete with traditional chemistry—it fundamentally reimagines it.

“We can switch our reactors on and off like a light switch, deploy them anywhere renewable energy exists, and serve both conventional syntheses and the valorisation of waste CO2, producing the exact chemicals our customers need.

“This funding gives us the resources to prove that sustainable chemistry isn’t just possible—it’s inevitable and profitable.”

One example is CF4, a potent greenhouse gas with a global warming potential 7,390 times stronger than CO2 that persists in the atmosphere for over 50,000 years. PFAS, also known as “forever chemicals,” resist natural degradation and accumulate in the environment and the human body.

Both are difficult to treat with conventional processes due to their ultra-stable bonds, creating a high-value market opportunity as companies face mounting regulatory pressure to address these pollutants.

“What excites us about enaDyne is that they are building a truly scalable platform technology for sustainable chemistry, while at the same time unlocking an immediate business case,” said Stefano Galiasso, Vice President at Energy Capital Ventures.

“The ability to rapidly eliminate ultra-stable PFAS emissions not only creates early commercial traction but also proves the versatility of the underlying plasma catalysis approach. This rare combination of near-term impact and long-term industry transformation is exactly what we are looking for in Green Molecules® at Energy Capital Ventures.”

The company has achieved significant technical and commercial milestones, including winning the SPRIND Carbon-to-Value Challenge and securing its first paying pilot customers. enaDyne has also been recognized with multiple awards.

Looking ahead, its long-term vision is to become the global platform for non-thermal plasma-based chemical synthesis, deploying tens of thousands of containerised units by 2050.

References

1. https://www.sciencedirect.com/science/article/pii/S2590332223002075 (accessed in July 2025)

2. https://www.sciencedirect.com/science/article/pii/S2590332223002075 (accessed in July 2025)

3. https://www.weforum.org/stories/2024/01/chemicals-closer-to-decarbonization/

4. https://www.spglobal.com/sustainable1/en/insights/special-editorial/decarbonizing-chemicals-part-one-sectorwide-challenges-will-intensify-beyond-2030

5. https://www.deloitte.com/us/en/insights/industry/chemicals-and-specialty-materials/chemical-industry-outlook.html