HRS Heat Exchangers, a leading global provider of efficient heat transfer solutions, has won its largest ever component order, valued at $3.8 million.

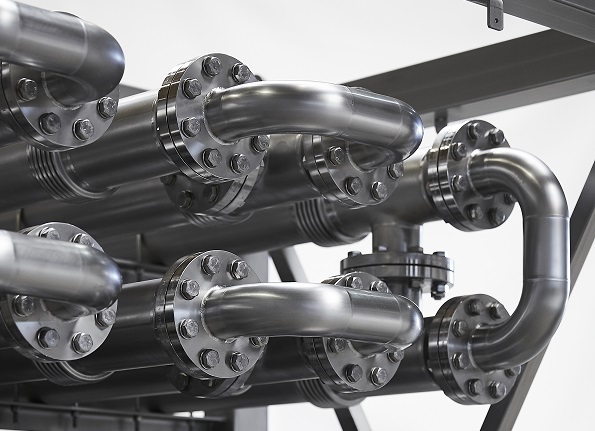

The heat exchangers, for a North American client, will form part of a major environmental project and are due for delivery in late 2024. They include a mixture of 6m and 10m long heat exchanger modules (384 in total), using almost 10 km of tube, and the efficient corrugated tube technology that HRS is known for. Together the exchangers have 2,268 flanges and more than 18,000 nuts and bolts.

The units are being constructed at HRS Heat Exchangers’ global manufacturing facility in Murcia, Spain, and once complete the 126 tonnes of equipment will be transported in 18 shipping containers. The system includes various modules to perform a range of heating, cooling and heat recovery operations as part of a renewable energy project.

Matt Hale, International Sales & Marketing Director at HRS Heat Exchangers, comments: “This order recognises the international teamwork which categorises the HRS business model, from the local sales and engineering team in North America, to the designers and engineers at our base in Spain. Everyone has worked hard to devise a solution which meets the client’s challenging brief. This order, which follows on from the production of our largest ever evaporator last year, underlines our continued global growth.”