Produced using a patented dry-spinning technology – CollaFibR™ from AMSBIO is a highly consistent collagen fibre matrix that closely mimics the biomechanical and biochemical properties of natural collagen scaffolds, offering a highly accurate representation of in-vivo conditions.

These innovative collagen fibres are seamlessly produced on a commercial scale using an automated state-of-the-art Good Manufacturing Process, catering to a variety of applications in 3D cell culture and tissue engineering.

Offered as a user friendly 12-well plate insert – CollaFibR™ scaffolds are perfect for creating physiologically relevant environments for 2D and 3D cell culture applications by inducing cellular alignment, migration, and elongation. AMSBIO can also offer custom CollaFibR™ scaffolds tailored to meet your specific needs, as our automated manufacturing process allows us to control the thicknesses, porosities, and alignment of our scaffolds with a high batch-to-batch consistency and higher cell viability.

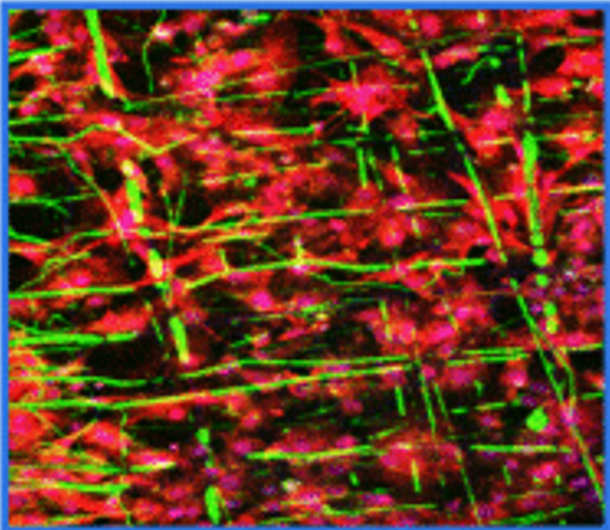

Available with a fluorescent tag, CollaFibR™ scaffolds are fully compatible with brightfield, epifluorescence, confocal and live cell microscopy. Supplied UV sterilized and ready-to-use, CollaFibR™ scaffolds are degradable with collagenase enabling quick and easy cell extraction.

CollaFiBRTM is also available as short dry spun 50 μm collagen fibres that can be used as an additive for bioinks and hydrogels. These GMP fibers increase the cellular viability, shape fidelity and biological relevance of bioprinted constructs.

Setting a new benchmark for cell culture consistency, CollaFibR™ scaffolds are enabling exciting innovation in applications such as 3D tissue culture, myelination studies and contract tissue engineering. For further information please visit https://www.amsbio.com/3d-cell-culture-extracellular-matrices/collafibr/collafibr-scaffold/ or contact the company on +31-72-8080244 / +44-1235-828200 / +1-617-945-5033 / info@amsbio.com.