Removal of phosphorous from industrial and municipal wastewater streams is commonly done using a process which involves the chemical precipitation of inorganic forms of phosphorous by adding a coagulant and mixing it with wastewater. This process achieves both phosphorus and other metals removal, along with suspended solids present in the wastewater as well as preparing the wastewater for further treatment in biological processes and DAF plants.

The coagulant and the inorganic phosphorous will result in a precipitate that can be removed as a sludge from the bottom of a process tank. This coagulant is often iron based, e.g. ferrous sulphate or ferric chloride. As ferric chloride contains chlorides, overusing this product might interfere with the correct operation of any subsequent biological treatment processes that follow. This is because of the action of chlorides as a disinfectant agent in high concentrations.

An alternative, user and environmentally friendly iron-based product is Ferromex by OMEX Environmental which is based on ferrous sulphate. As Ferromex does not consist of any chlorides, the action of biological organisms will not be inhibited, and the removal of phosphorous can still be achieved to an equally high degree. Ferromex also benefits from having a higher pH, which results in reduced impact of material corrosion when compared to using solutions with lower/ more acidic pH values.

Case Study – Removal of Total and Soluble phosphates from an industrial wastewater using iron-based products

The two iron-based products included Ferromex 620 and a standard, industrial grade Ferric chloride product. Both products removed both soluble and total phosphorous from the wastewater, with each product having optimal settling times and pH ranges.

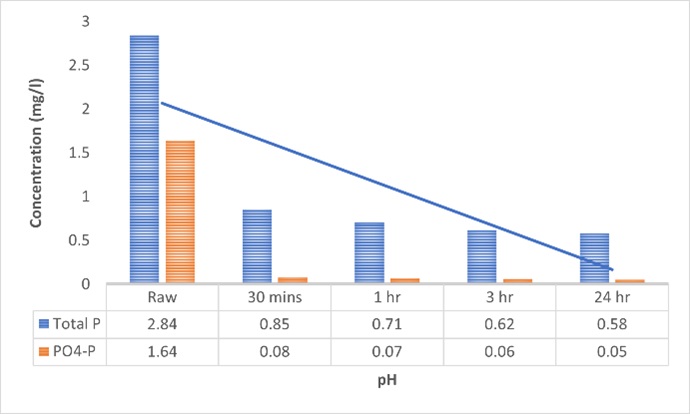

For Ferromex 620, the optimum pH range was 5.0 – 5.3. After 30 minutes of settling time, up to 95% of the soluble phosphorous and up to 70% of the total phosphorous had been precipitated out into the sludge. Both soluble and total P removal rates increased over 24 hours with up to 97% soluble P and up to 80% total P removal, when compared to the initial wastewater phosphorus concentrations.

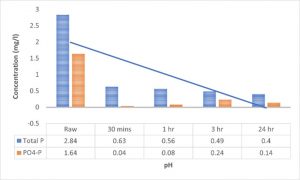

For the Ferric Chloride product, optimal pH range was 4.95 – 5.6. 30 minutes of settling time allowed a soluble P removal of 98% and a total P removal of 78%. However, it was found that as the settling time was increased and after 24 hours, some of the soluble P that had been removed into the sludge, redissolved into the supernatant liquor. This resulted in only 91% of soluble P being removed. A small increase in the total P removal was also observed after 24 hours.

Ferromex has been engineered in such a way, that it provides the product with natural antifreeze properties. The product is fully compatible with the biochemical cycles in a biological wastewater treatment plant. This helps the product better withstand exposure to adverse weather conditions and hence minimise the effects of the product freezing or crystalising in storage tanks and containers.

OMEX offer full support with the product during application by analysing samples throughout the process in their fully equipped laboratory, in order to recommend process optimisation solutions.

Visit www.omex.co.uk or email environmental@omex.co.uk

Omex Environmental Ltd, Riverside Industrial Estate, Estuary Road, Kings Lynn, Norfolk, PE30 2HH. Tel +44 (0)1553 770092