With the uncertainty we are experiencing in relation to climate change and rising costs, professionals involved in process safety are confronted by a decision – keep project costs down or think about the bigger picture and try and to make a project as sustainable as possible over its entire life.

We believe that adopting sustainable practices is not only the right thing to do, but it also makes good business sense. Integrating sustainability into projects is essential for businesses that want to achieve the following goals:

- Reducing your ecological footprint

- Making a more marketable product

- Minimising waste

- Reducing operating costs

Short term vs Long Term Costs

Naturally, financial costs are one of the most influential factors when making business related decisions, so reluctancy to spend big sums on making changes to your plant in order to make it more sustainable is understandable. However, this is not to say that avoiding doing so is the most cost-effective option in the long term. The initial costs can be offset in several ways, and this requires a focus on capital expenditure (CapEx), as well as just Operational Expenditure (OpEx). By considering both the initial purchase and installation costs (CapEx) plus the operating costs (energy and maintenance costs) for the life of the equipment (OpEx), initial purchase price differences can be quickly overridden by operating cost savings. Applying this same logic to other areas of your project (utilities, emissions, location, raw materials, sustainability of manufacturer etc. ) can mean that sustainable practices can actually be financially beneficial to your business down the line, not to mention the inevitable positive impact on a company’s reputation and brand image.

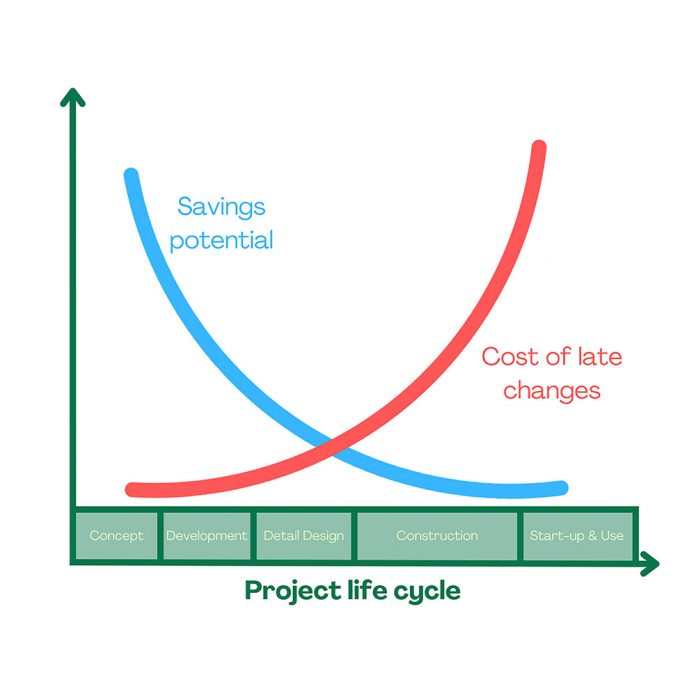

For projects, it is particularly important to think about sustainability early in the design as it is more cost effective to make changes on paper and invest earlier on than it is to make changes to an already established and operating plant. Generally, the later in the project life cycle that changes are integrated, the greater the costs, and on the contrary the earlier any changes are introduced, the greater the potential savings in the long run. This got us thinking about the parallels with what process safety. We promote Inherent Safety, so why not Inherent Sustainability?

Sustainability in relation to Hazard Studies

We believe that with relatively small changes to established and embedded hazard study processes, sustainability can be thought about at the right time to maximise the potential benefits. For example, Hazard Study 2 (HAZID) provides a perfect opportunity to consider more sustainable options, at this point the overall aim of the project is understood but the project has not yet reached a stage where changes are extremely costly, both in time and money (e.g. detailed P&IDs have not yet been drawn).

Hazard studies provide a natural forum to consider factors such as alternative technology that uses less energy, less raw materials, recovers more product, requires less maintenance, uses fewer consumable parts, or reduces the requirements for subsequent processing. Hazard studies can also be used to identify opportunities to reduce emissions and waste.

Integrate for Effective and Positive Change

Sustainability must be embedded as a company goal to have the greatest impact. Integration into existing hazard study processes is a realistically achievable approach. Introducing sustainability into the process safety management processes could have far-reaching benefits.

RAS will be at the 33rd IChemE Hazards Process Safety Conference to discuss this and other important topics. Join us on the 7th-9th November in Birmingham!

Rob Ritchie and Carolyn Nicholls