What is Green Chemistry? Is this only a buzz word that is used to give a more positive image of the Chemical Industry, or it is a true concept influencing Chemical Companies to adapt their behaviours and activities at their production sites?

The concept of Green Chemistry continues to gain momentum in the Chemical Industry and describes taking an environment-driven approach to reduce environmental and health impacts from chemicals by minimising pollution or saving energy. It is becoming increasingly important that the products being manufactured, and processes involved contribute towards a sustainable future.

Klüber Lubrication is part of Freudenberg Chemical Specialities – a chemical company itself, so consequently we know the challenges the Chemical Industry face. Local production, local material sourcing, installing solar energy to our sites, optimizing our processes to improve efficiency, generate less waste and implementing a safety-first philosophy in our operations are only a few things we do on our end to get in line with Green Chemistry, but Green Chemistry is more than just aiming towards substantiable operations and reducing GHG emissions.

Green Chemistry has 12 clear principles that touch various topics including of course sustainability, efficiency, and environmental, but also extend to subjects like safety and the circular economy. Klüber Lubrication has never stopped improving its processes according to these 12 principles to reduce its footprints on the environment.

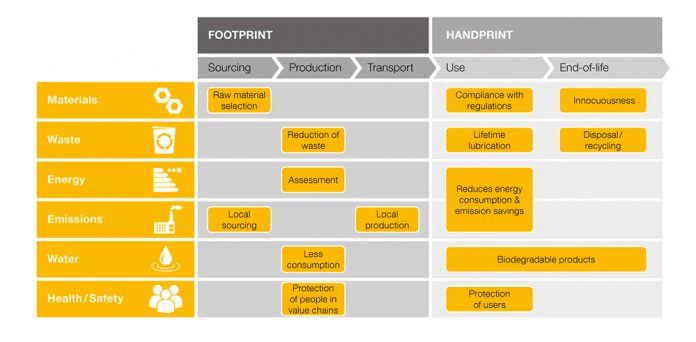

We attach so much importance to Green Chemistry that we have created our own sustainability matrix to measure our progress in this regard.

How can Lubrication Solutions contribute to

Green Chemistry?

Lubrication is not the first thing that comes to mind when our customers’ want to fulfill their Green Chemistry principles, however as a lubricants manufacturer we know that the choice of a suitable lubricant solution is an important factor of sustainability and that we can have a positive impact on at least half the 12 Green Chemistry principles.

Our high-performance specialty lubricants and individual services offer many benefits:

Reliability: This is the decisive factor to be considered when starting a project to optimise your lubrication processes. It is the one aspect that must never be jeopardised

Energy efficiency: Energy savings are possible in many of your installations using the right lubricant. We can prove energy savings and carry out projects that comply with internationally recognised standards such as the International Performance Measurement and Verification Protocol (IPMVP) or DIN ISO 50015.

Plant availability: The long service lives of our lubricants extend the operation of your plant and reduce the need for maintenance

Safety: Our specialty lubricants and Klübermatic lubricant dispensers offer the maximum safety in areas exposed to explosion risks

Optimisation: We carry out lubricant analyses, oil condition monitoring, equipment labelling and fault analyses

Clear overview: We can help you consolidate your lubricant inventory and lay out your lubricant storage site

Sustainability: Less waste and lower lubricant consumption. Ecovadis, a leading provider of sustainability ratings for corporations, has rated our sustainability management with its gold medal. This grades Klüber Lubrication among the best 6 % of over 90,000 companies rated worldwide

At Klüber Lubrication, our quest to reach Green Chemistry excellence is a never-ending story. We are proud of what we achieved over the past years and hope to do more to keep our highly engineered world moving in a way that is sustainable for us and the future generations.

Email: info@uk.klueber.com

www.klueber.com/uk/en