A new bio-inspired zeolite catalyst has been developed by an international team comprising researchers from Technische Universität München, Eindhoven University of Technology and University of Amsterdam.

The researchers say that it might pave the way to small scale ‘gas-to-liquid’ technologies, converting natural gas to fuels and starting materials for the chemical industry.

By investigating the ooxidation of methane to methanol, they identified a trinuclear copper-oxo-cluster as the active centre inside the zeolite micropores.

The development is important because, in an era of depleting mineral oil resources, natural gas is becoming ever more relevant, even though the gas is difficult to transport and not easily integrated in the existing industrial infrastructure.

One of the solutions for this is to apply gas-to-liquid technologies. These convert methane, the principal component of natural gas, to so-called synthesis gas from which subsequently methanol and hydrocarbons are produced. These liquids are then shipped to chemical plants or fuel companies all over the world.

This approach is only feasible at very large scales and currently there is no ‘gas-to-liquid’ chemistry available for the economical processing of methane from smaller sources at remote locations.

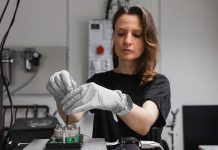

A research team combining Moniek Tromp (UvA/HIMS), Evgeny Pidko and Emiel Hensen (Eindhoven University of Technology), Maricruz Sanchez-Sanchez (Technische Universität München) as well as Johannes Lercher (Technische Universität München and Pacific Northwest National Laboratory) is focusing on a bio-inspired method enabling such partial methane oxidation.

Their focus is a modified zeolite, a highly structured porous material, developed at Lercher’s research group in Munich. This copper-exchanged zeolite with mordenite structure mimics the reactivity of an enzyme known to efficiently oxidize methane to methanol.

In a recent paper, the researchers outlined how the zeolite mimics the active site of the enzyme methane monooxygenase (MMO).

The researchers showed that the micropores of the zeolite provide a perfect confined environment for the highly selective stabilisation of an intermediate copper-containing trimer molecule.

Professor Johannes Lercher said: “The developed zeolite is one of the few examples of a catalyst with well-defined active sites evenly distributed in the zeolite framework – a truly single-site heterogeneous catalyst.

“This allows for much higher efficiencies in conversion of methane to methanol than with zeolite catalysts previously reported.””