A new report has shown that the Appalachian region could become a second centre of American petrochemical and plastic resin manufacturing, similar to the Gulf Coast.

The report was compiled by the American Chemistry Council (ACC), whose President and CEO Cal Dooley said: “The Appalachian region has distinct benefits that could make it a major petrochemical and plastic resin-producing zone.

“Proximity to a world-class supply of raw materials from the Marcellus/Utica and Rogersville shale formations and to the manufacturing markets of the Midwest and East Coast has already led several companies to announce investment projects, and there is potential for a great deal more.”

ACC’s report is based on a hypothetical scenario that includes the development of a storage hub for natural gas liquids (NGLs) and chemicals (e.g., ethylene, propylene), a 500-mile pipeline distribution network and associated petrochemical, plastics and potentially other energy infrastructure and manufacturing in a quad-state area consisting of West Virginia, Pennsylvania, Ohio and Kentucky.

According to the ACC, the economic benefits could be substantial. By 2025, the region could see 100,000 permanent new jobs, including 25,700 new chemical and plastic products manufacturing jobs, 43,000 jobs in supplier industries and 32,000 jobs in communities where workers spend their wages, according the report.

The new investment could also lead to $2.9 billion in new federal, state and local tax revenue annually.

Cal Dooley said that the support of politicians was important to turn the theories into reality, adding: “The right policies are critical to realising this opportunity. Uncertainty around financing is a key barrier to the development of energy infrastructure in the Appalachian region.

“Policymakers can help by affirming that NGL storage and distribution projects are eligible for existing private-public financing programmes. As Congress and the Administration consider infrastructure modernisation legislation, the Appalachian Hub should be a priority.”

ACC’s analysis projects a $32.4 billion investment in petrochemicals and derivatives and a $3.4 billion investment in plastic products, put toward the construction of five ethane crackers and two propane dehydrogenation (PDH) facilities.

Three of the crackers would produce polyethylene and two would supply downstream petrochemical derivatives. Each PDH facility would contain a polypropylene resin plant. These capital investments are already under way and will likely continue through the mid-2020s.

Plentiful and affordable supplies of natural gas and NGLs are enabling companies from around the world to build new U.S. facilities or expand production capacity.

Since 2010, 301 projects cumulatively valued at $181 billion have been announced, with nearly half completed or under construction.

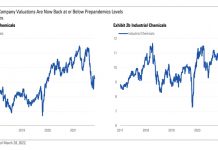

• According to the American Chemistry Council (ACC), the U.S. Chemical Production Regional Index (U.S. CPRI) edged higher by 0.1 percent in April, following flat growth in March, and a 0.3 percent decline in February.

During April, growth in the Midwest, Mid-Atlantic, Southeast, Northeast and West Coast regions was offset by declines in the Gulf Coast and Ohio Valley regions.

There were gains in the production average output trend of pharmaceuticals, fertilizers, coatings and adhesives. These gains were offset by declines in the output trend in synthetic rubber, pesticides, other specialties, plastic resins, consumer products, organic chemicals, chlor-alkali, industrial gases, other inorganic chemicals and manufactured fibres.